Plasma cleaning for UHV applications: particle accelerators

Hyper-clean Surfaces

UHV critical components, such as those used extensively in surface science laboratories and particle accelerators, are required to meet strict cleanliness criteria of which pre-installation cleaning is an important step. Daresbury Laboratory based in the UK and a centre for worldwide particle accelerator technology, approached Henniker Plasma to look at the potential of oxygen plasma cleaning as part of the stringent pre-cleaning process.

Plasma cleaning was assessed by measurement of electron stimulated desorption yields. Together, we were then able to compare the results from using traditional solvent-based cleaning together with plasma cleaning.

Solvent Cleaning Technique

A hydrofluoroether (HFE) type solvent was employed at Daresbury Laboratory as the primary cleaning solvent of choice, having been chosen from the outcome of earlier studies of the effects of various cleaning techniques on outgassing and electron stimulated desorption from stainless steel [1].

The steps used in the HFE procedure are as follows;

- 1. Manual detergent wash

- 2. Rinse in de-mineralised water

- 3. 15 minutes of aqueous wash using a standard detergent

- 4. Rinse in de-mineralised water

- 5. 15-minute ultrasonic clean in HFE

- 6. 15-minute vapour clean in HFE

- 7. Rinse in de-mineralised water

- 8. Dry in the oven (80°C)

Plasma Cleaning

When gas atoms are ionised, the collision of high energy particles knocks electrons out of their orbits. This results in the characteristic “glow” or light associated with plasma. Plasmas contain many different species including atoms, molecules, ions, electrons, free radicals, metastables, and photons in the short wave ultraviolet (vacuum UV or VUV) range. Plasmas are generated in closed vessels at low pressures, typically < 1.0 Torr. The low pressure results in a long mean free path of the plasma species so that they remain reactive until contact with a surface. The overall chamber temperature at the commonly used power levels and pressures is close to room temperature.

The gas used in these experiments was oxygen. The VUV energy is effective in breaking the organic bonds (i.e., C-H, C-C, C=C, C-O, and C-N) of surface contaminants. This helps to break apart high molecular weight contaminants. A second cleaning action is carried out by the oxygen species created in the plasma (O2+, O2-, O3, O, O+, O-, ionised ozone, metastably-excited oxygen, and free electrons). These species react with organic contaminants to form H2O, CO, CO2, and lower molecular weight hydrocarbons. These compounds have relatively high vapour pressures and are easily evacuated from the chamber.

Measurement of Sample Cleanliness

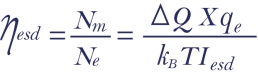

Stainless steel samples were first contaminated with a variety of contaminants including oils, grease, fingerprints and marker pen. Sample cleanliness was then assessed by measuring the electron stimulated desorption yield, calculated by the throughput at the conductance:-

Where Nm= number of desorbed molecules, Ne= number of incident electrons, qe= electron charge, kB= Boltzmann’s constant, T= chamber temperature, Iesd= drain current, Q= throughput.

Figure 1. ESD Experimental Arrangement

- - Other essential features of the experiment were:

- - Cylinder biased to +200V

- - Coaxial electron source

- - Variable conductance: 143 ltr.sec-1 (mass 28) for ESD

- - Calibrated pressure measurement

- - Sample drain current measured during ESD

Results and Discussion

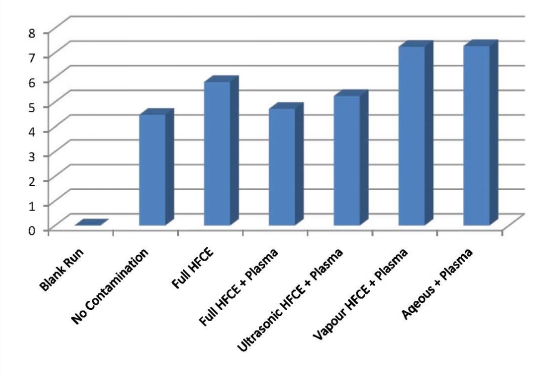

The results shown in Chart 1 demonstrate that there is a clear improvement in electron stimulated desorption yield (sample cleanliness) when plasma cleaning is used in addition to the solvent cleaning procedure described.

The measured electron stimulated desorption yield with the additional plasma cleaning step is almost the same as the yield from the uncontaminated samples. For this specific work, this result suggests that plasma cleaning could add benefits to vacuum components used in an accelerator environment due to the reduction in desorption yield and hence a smaller gas load to contend with.

The results of samples subjected to a reduced cleaning cycle in conjunction with plasma cleaning (ultrasonic HFE + plasma) are also better than the results obtained from the samples that had undergone the full HFE cleaning process. This suggests that the full HFE cleaning process could be reduced to just two stages, ultrasonic and plasma, and still produce samples of higher cleanliness.

Chart 1. Comparison of Cleaning Methods via Electron Stimulated Desorption Yield (molecules/electron)

The remaining samples (aqueous or vapour clean + plasma) all show similar results in that they are insufficient combinations of cleaning steps to produce UHV clean samples.

Our Solution

Using our bench-top plasma cleaner in combination with the traditional solvent-based cleaning routine described here produced cleaner surfaces, similar to those of uncontaminated surfaces, than solvent-based cleaning alone.

This example demonstrates that Plasma cleaning can

- i) Reduce lengthy cleaning processes

- ii) Reduce the use of environmentally unfriendly solvents

- iii) Reduce the costs associated with handling, use and disposal of solvent-based cleaners.

The Daresbury Laboratories team worked closely with Henniker Plasma to ensure a solution which enhanced and determined their own objective in becoming a worldwide leader in particle accelerator technology.

"Using our bench-top plasma cleaner in combination with the traditional solvent-based cleaning routine described here produced cleaner surfaces, than solvent-based cleaning alone."

——K.J.Middleman Daresbury.

Reference[1] K.J. Middleman, Vacuum 81 (2007) P793-798.

Source of the original text:

LIST

LIST